What is gold leaf?

Gold leaf stands as a testament to the exquisite craftsmanship in art and sign making. The traditional process involves the compressing gold into thin layers. Artists and sign makers alike, desire gold leaf for its unparalleled ability to elevate the mundane to the extraordinary. Whether it’s adding a touch of sophistication to carved letters or a shimmering accent on glass, gold leaf brings a timeless elegance to any project.

The variety of gold leaf, from the deep glow of 22-karat yellow gold to the subtle elegance of palladium and white gold, offers a wide palette for creative expression. Additionally, variegated leaf introduces many new colors, enriching designs with its diverse beauty. Each type of metal leaf contributes its distinct charm, making gold leaf a versatile and cherished material in the creative world.

How is gold leaf made?

The creation of gold leaf is a testament to the delicate balance between strength and fragility. Artisans take pure gold and embark on a labor-intensive process, meticulously hammering and stretching it to produce verythin sheets. This transformation requires not just physical effort but also a deep understanding of the metal’s properties.

Through relentless beating, the gold is worked into sheets that are almost ethereal in their thinness. The sheets become so fine. They achieve a level of transparency, a remarkable characteristic that allows light to pass through. This quality makes gold leaf an exceptional material for artists and craftsmen who aim to infuse their creations with true brilliance.

Careful handling

Handling gold leaf is an exercise in precision. Its consistency is incredibly delicate, to the point where a mere touch can cause it to disintegrate. This sensitivity requires a gentle hand and tools designed to manipulate the leaf without directly contacting it. It’s fragility requires sign makers and glass artists to approach their craft with the utmost respect and care.

The end use of these shimmering sheets is diverse. They are most commonly seen adorning the surfaces of signs and windows, where they elevate the ordinary into the realm of the extraordinary. The gold leaf’s ability to catch and play with light adds depth and dimension, turning a simple sign into a statement and a pane of glass into a canvas for radiance.

In this craft, the choice of gold leaf can vary widely, offering a palette for every aesthetic. From the deep, rich yellow of 22-karat gold to the subtle sheen of white gold and the textured hues of variegated leaf. Each variation offers its own unique contribution to the artist’s vision. In all its forms, gold remains an enduring emblem of luxury. For those who create with an eye for beauty and a hand for detail, gold leaf is essential.

What is gilding?

Gold leaf boat lettering

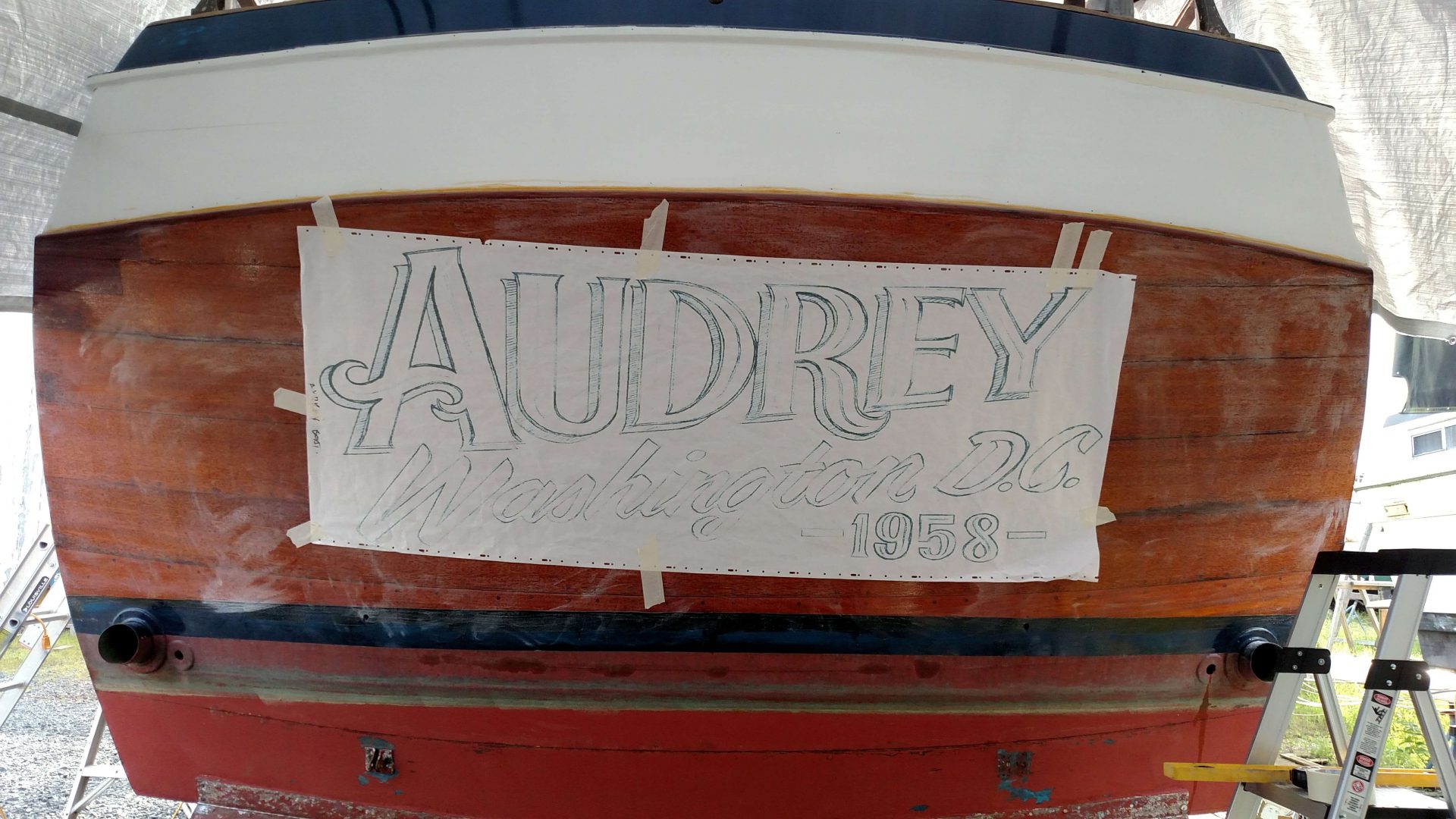

Hand-applied gold leaf lettering holds a special place in maritime lor. It embodies a tradition of gilding that has sailed through centuries, unchanged by the winds of time. Various techniques exist for affixing gold leaf, including engine turning. Sign makes use a piece of soft fabric to gently burnish the leaf in a circular pattern. This method creates a textured, scaled effect that magnificently catches and plays with light and the reflections of water. Adorning your yacht’s transom with gold leaf lettering adds a touch of elegance, allowing you to navigate the waters with unparalleled style.

For those with fishing trawlers, incorporating bold, customized names and graphics in gold leaf can set your vessel apart. Undoubtedly, for enthusiasts of classic wooden boats, employing traditional 23-karat gold leaf for the vessel’s name infuses it with a timeless beauty. Foundationally, this intricate craft not only enhances the aesthetic of boats but also connects them to a rich heritage of maritime elegance.

Applying leaf to boats

Applying leaf lettering to boats begins with a meticulous process to ensure precision and beauty. Initially, we create the outline of the lettering on the transom of the boat. We use pounce patterns or stencils to complete the task accuratley. Next, we carefully apply the size, allowing adequate time for it to dry. Then we apply the gold quickly before the size has dried completely. Timing is critical during the step. If applied too soon the leaf will sink. Sinking gold loses it’s luster. If applied too late the leaf the size would be too dry to accept the leaf. As a result the leaf will fall off.

Next, we detail the letters with outlines and shading. Yes, this absolutely enhances the visibility and impact of the lettering against the background. This careful attention to detail ensures a vibrant contrast that makes the lettering stand out. Completing this intricate process typically requires about five hours. Our patience is a testament to the craftsmanship and dedication involved. This method not only beautifies the boat but also adds a layer of personalized elegance to its appearance.